Millwright Mechanical Technician

Overview

Anywhere there's industrial equipment, a Millwright is required to install, repair, maintain, and modify that equipment. Explore the variety of places a Millwright can work - the possibilities are endless.

This program is well suited for those who enjoy working with mechanical applications. Students are provided with the skills necessary to safely install, troubleshoot, overhaul and maintain a variety of mechanical equipment used in industrial operations. The program also integrates best practices commonly used in the industry. Areas of study include: machining, blueprint reading, hydraulics and pneumatics, electronic, power transmission and lubrication, materials science, preventative and predictive maintenance, project management, PLC, Robotics, CNC, and 3D modeling.

The Mechanical Technician – Industrial Maintenance (Millwright Mechanical Technician) program is recognized by the Ministry of Colleges and Universities as a co-op/diploma program. Graduates meet the program standards of an Ontario Mechanical Technician, as well as the in-school training of an Industrial Millwright Apprenticeship.

Students who are in good academic standing during the first two terms of the program will be eligible to apply for a four-month co-op job placement as available. A student is considered to be in good academic standing if they have passed all of their courses and have maintained a GPA of 2.5 or greater. Students seeking co-op job placement positions must apply for them and be chosen following an interview process. The college actively pursues companies to participate in the program but cannot guarantee co-op placements for each student.

Please Note: Equipment and hand tools are available onsite for use during the duration of the program.

Let Colin explain the exciting career of a Millwright

"I was the most experienced person at my first job after Lambton College - just for the virtue of having a co-op. My co-op was awesome!"

- Colin McDonald, MTIM Graduate

Admission Requirements

O.S.S.D. or equivalent with:

- Grade 12 English C or U

- Grade 12 Mathematics C or U

- Grade 11 or 12 Physics C or U (recommended)

Grade 12 Mathematics Requirement

Grade 12 Mathematics for College Technology or any grade 12U mathematics is recommended; Grade 12 Foundations for College Mathematics (MAP4C) minimum final grade is 60%. If the program is highly competitive, students with Grade 12 Mathematics for College Technology or any Grade 12U mathematics will be given preference.

Mature Student Assessment for this program is available in the subject of English for the purpose of demonstrating proficiency in this required admission subject. For all other admission requirements, applicants must complete the required course(s) as listed above. For more information, please contact counselling@lambtoncollege.ca. Review the Mature Student Admission process.

Academic admission requirements can be obtained through Academic Upgrading and the Pre-Technology & Trades (PTEC) program at Lambton College.

Women in Technology & Trades

Discover how Lambton College's Women in Technology & Trades (WiTT) group is empowering women to excel in technology and trades.

Visit our WiTT page for more information on mentorship opportunities, events, and resources designed to support your journey in these dynamic fields.

Learn More

Costs

- Year 1 $4,634.34

- Year 2 $4,548.42

Please Note: These fees apply to the 2024-2025 academic year and are subject to change. Fees do not include books (unless specifically noted), supplies or living costs.

Additional Fees

-

Calculator$24.00

-

Safety Shoes$150.00

-

Safety Glasses$20.00

Welding Clothing

Students will be expected to purchase the following from Acklands-Grainger:

- Welding Gloves

- Helmet

- Jacket

These items are purchased in-class and cost will be determined at the time of purchase.

Scholarships Available

There are 14 scholarships available for this program, with a total value of $4,750!

Technology Requirements

In order to keep pace with the requirements of each and every course in your program, Lambton College requires that each student have access to a laptop while studying at our college.

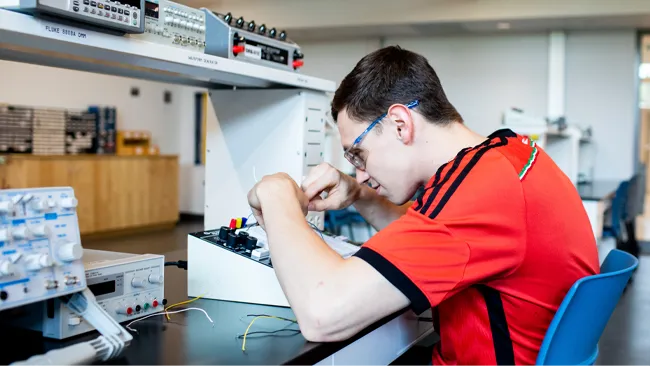

Labs & Equipment

Courses

Maintenance Tools & Techniques

This course will cover the fundamentals of Machine Shop, hand and power equipment, measuring tools, materials, and practices. The students will learn to function safely in the work environment, select and use references, tools, methods, and procedures, to create and alter mechanical components to given specifications. Theory will include safety, precision measurement, hand tools, power hand tools, machine tools and cutters.

Basic Engineering Drawings

Millwrights and technicians require the ability to sketch, read, and interpret engineering drawings and schematics. These skills are necessary in order to comply with drawing standards and specifications while installing and maintaining machinery. Topics in this course include orthographic projection, multi-view projection, dimensioning, the title block and drawing notes. A variety of view types will be examined including auxiliary, assembly, detail, isometric and section. As well, an introduction to welding symbols and geometric tolerances will be covered.

Rigging & Hoisting

This course is designed to develop knowledge of the safety legislation involved with hoisting, lifting and machine moving as well as the procedures involved. This course will enable the student to plan lifts, perform calculations using load charts, select and use correct rigging & hoisting equipment, inspect and maintain equipment, use hand signals, control load balance and direct and disassemble all equipment safely.

Workplace Communications

This course focuses on skills required in any organization or position: writing business documents, responding to realistic scenarios, and speaking in an organized and vibrant manner. Students will practice professional and inclusive communications skills by producing, revising, and editing short business documents and engaging in verbal interactions and presentations.

Job Search & Success

This course provides student with skills and knowledge to help support their career search and succeed in the workplace. Students align their personal skill set and goals to guide them on their career paths. They will learn how to effectively conduct a job search, build a professional and well-tailored resume and cover letter, and develop and practice interview techniques. Students will also develop their personal brand to help support effective career networking and aid in their job search. Teamwork and collaboration in the workplace are also discussed. Self-reflection is used to inspire insight and support their professional career journey.

Mechanical Mathematics I

This is the first of two courses on technical mathematics, designed specifically for the Mechanical Technician Industrial Maintenance program. It reviews and develops topics in computation, measurement, algebra, and geometry, emphasizing technical applications.

Safety & Welding Basics

This course is designed to develop knowledge of general safety practices and operating principles of OFC/OFW (oxy-fuel cutting/welding), brazing, PAC (Plasma Arc Cutting), and semi-automatic welding equipment (Gas Metal Arc Welding-GMAW, Flux Cored Arc Welding-FCAW, Metal Cored Arc Welding-MCAW). Emphasis will be given to cutting and welding in the flat and horizontal positions. All industrial operations entail potential risks to health and safety, especially when welding. The intent of this course is to minimize these hazards by providing the student with the skills to comply with all safety rules and procedures involved in the industry.

Introduction to Pumps, Machines & Piping

This course is a survey of the aspects of pumps, piping and conveyor systems applicable to Mechanical Technicians in the Industrial Maintenance program. Millwrights working in the trade will be involved with many different types of equipment including pumps, piping systems and conveyors. The millwright must be familiar with the different types of pumps, their unique features and how they are maintained. Piping systems are associated all other plant equipment. This piping must be selected, installed and maintained. The student will develop knowledge regarding types, selection and the principles of operation of various materials handling systems. The knowledge obtained is considered as background for other technical courses including Preventive and Predictive Maintenance.

Maintenance Machine Shop

This course will focus on the advanced techniques of machine tool operations. The students will learn to set-up and repair machine and equipment components, select and use appropriate materials, references, tools, methods, and procedures. Theory will include references for shafts, couplers, drivers, metals and heat treatment of metals. For mechanical equipment to have a long life it must be assembled while maintaining alignment and clearances to close tolerances. The practices in this course refine the skills and disciplines that the machinist uses to establish and maintain alignments, fits and clearances.

Advanced Engineering Drawings

Millwrights and technicians require the ability to sketch, read, develop and interpret engineering drawings. These skills are necessary in order to comply with drawing standards and specifications while installing and maintaining machinery. Topics in this course include developing Engineering Drawings using AutoCAD (2D) and Solidworks (3D). Computer Aided Design (CAD) Software is used for the creation and modification of parts, assemblies and drawings. The construction and constraining of assemblies will be covered as will the creation of part and assembly drawings using the software.

Power Transmission, Bearings & Lubrication

This course is designed to prepare the student to disassemble, service and recommission the components in power transmission applications. These applications include belts and pulleys, chains and sprockets, shafts, speed reducers, gears, brakes, clutch mechanisms, harmonic drives, couplings, cams and followers, keys, splines, bushings, bearings and seals. Students will be introduced to the types, properties and application of lubricants. Students will perform associated trade calculations and interpret engineering and component drawings, ISO charts, and bearing catalogues to ensure that work performed conforms to specifications. Millwright technicians are required to perform various tasks related to removal, maintenance and the installation of power transmitting components. They must follow safety guidelines, manufacturers? specifications and company procedures. They must understand the workings of assembly components and be able to communicate effectively with manufacturers, engineers and skilled trades workers.

Mechanical Mathematics II

This course continues MTH 1253. It covers trigonometry ratios and graphs, vectors, exponential and logarithmic functions, and probability and statistics.

Advanced Welding & Fabrications

This course is a continuation of WEL-1123. It is intended to develop additional knowledge and skills in welding practice, techniques and the pertinent regulations. An understanding of welding symbols, as portrayed on drawings, layout and set-up, metal preparation, electrode selection, Gas Tungsten Arc Welding (GTAW), Shielded Metal Arc Welding (SMAW) and Carbon Arc Cutting with Air (Gouging, CAC-A) techniques will be developed. The student will develop the knowledge and capability to read drawings and safely layout, measure, cut, tack, fabricate, weld and assemble metal and other components to specifications. Various shop projects with industrial and construction applications will be planned and assembled using the appropriate tools and equipment. Welding practices and procedures are essential skills.

Schematics & Cataloguing

Millwrights are required to interpret engineering drawings and how components exist separately and how they interact with one another. This knowledge is then used to disassemble machinery, order replacement parts, rebuild and maintain. This course introduces students on how to effectively use manufacturer's catalogues, technical manuals and engineering drawings to select components according to specifications and functional needs.

Co-op Work Term (optional)

Co-operative education provides students with the opportunity to apply classroom learning to the workplace, undertake career sampling and gain valuable work experience that may assist students in leveraging employment after graduation.

Pneumatics & Hydraulics

This course develops an understanding of the basic principles and applications of pneumatics and compressed air safety as it relates to pneumatic systems. Basic hydraulic principles and the ability to perform pertinent hydraulic calculations, install, maintain and troubleshoot components will also be covered. Valves are used extensively in pneumatics, hydraulics and throughout all sections of industry. Knowledge of valve types, purposes and correct selection for specific systems will be covered. The operation, function and maintenance of ventilation, dust collection and cooling towers will also be included.

Basic Science & Mechanical Theory

This course provides an introduction to the principles of physical science as it pertains to the Millwright trade. Subjects include thermodynamics, applied mechanics, strength of materials, and waves. Students are required to use problem solving skills to complete analytical exercises and to produce written lab reports.

Electrical Fundamentals

This course introduces electrical principles that are fundamental to the operation and control of industrial equipment. Topics include: safe practices, electrical terminology, symbols, AC and DC circuit analysis principles, introduction to transducers, transformers and how DC and AC electric motors operate and are controlled. A laboratory component runs concurrently with the lectures. Lecture and laboratory are designed and scheduled to supplement and reinforce the learning outcomes of the course.

Advanced Compressors & Pumps

This course is a comprehensive study of rotating and reciprocating industrial equipment including pumps, compressors and turbines. Affiliated equipment used to safely operate the above listed is also included in this study. Mechanical Maintenance Technicians require the ability to perform a wide variety of tasks to high standards, as specified in maintenance procedures, in a safe and cost effective manner. Understanding the design features, operation and maintenance requirements of this equipment will enhance troubleshooting skills to perform inspection and repair as needed. Knowing the workings of this machinery will enable the student to communicate effectively regarding specific repairs and adjustments.

General Education Elective (Select 2)

Industrial Materials & Metallurgy

This course is designed to provide the student with an enhanced understanding of industrial materials of construction and metallurgy. Materials studied will include ferrous and non-ferrous metals as well as non-metallic materials. Properties, selection and applications of various materials, corrosion awareness, failure analysis and application of simple NDE will be examined. Why materials are selected for certain applications and how they are affected by their manufacturing methods and their environment will be studied. The properties and aspects of materials have direct bearing on the application for a specific use. Metallic and non- metallic materials have evolved and the wide range of materials available today can be staggering. Corrosion and material failures occur and a good understanding of these topics as well as non-destructive examination is required of maintenance personnel to provide continued safe plant operations.

Preventive & Predictive Maintenance

This course introduces students to the procedures, equipment, benefits and differences between the various types of maintenance programs. Students will be exposed to topics including vibration monitoring and analysis, dynamic balancing, non-destructive examination, lubrication and oil analysis. Students will learn how to maintain and utilize historical data, develop analytical and basic troubleshooting skills, analyze problems, and formulate the corrective sequence of actions. Laboratory exercises provide students the opportunity to actively engage with a variety of equipment and activities associated with a PPM program.

Industrial Automation

With the arrival of industry 4.0, automated systems have become more powerful than ever before. Robotic and PLC systems are now commonly placed in most of today's industries. This integrated lecture/laboratory course will introduce learners to the fundamentals of automated systems. Students will be required to write PLC programs in ladder logic that will perform tasks and control equipment. Students will also learn how to program and operate robots in a safe manner by studying the various safety systems that are a major component of automated robotic cells.

Shutdown Lean Manufacturing

This course provides students with a practical understanding of a Lean Production System. They develop continuous improvement skills, while actively identifying and eliminating all types of waste. Opportunities to improve processes and systems based on work analysis are provided. Topics including 5S, TPM and Visual Controls are also focused on.

Turbines & Prime Movers

This course is a comprehensive study of turbines, internal combustion engines and electric motors. Types, applications and maintenance procedures of prime movers will be examined. Mechanical Maintenance Technicians require the ability to perform a wide variety of tasks to high standards. They are required to complete these tasks as specified in maintenance procedures, in a safe and cost effective manner. Understanding the design features, operation and maintenance requirements of this equipment will enhance troubleshooting skills to perform inspection and repair as needed. Knowing the workings of this machinery will enable the student to communicate effectively regarding specific repairs and adjustments

General Education Elective

Contact

Program Information

Applied Science, Engineering Technology & Trades

After Graduation

Employment Opportunities

As one of the largest trades and a vital component in most organizations, millwrights have a wide range of potential employment opportunities. Graduates of this program have found careers in industries such as, but not limited to, refineries, nuclear power, manufacturing, and energy, automotive and food processing sectors.

Accreditations & Certifications

Millwright Apprenticeship

Graduates employed in Ontario are exempt from having to take the three levels of in-school Millwright Apprentice training and from having to take the exemption tests. Graduates have the choice of seeking employment as a mechanical technician or a millwright apprentice. Those choosing to become Ontario registered millwrights are required to complete their on-the-job millwright apprentice competencies as well to pass a Certificate of Qualification (C of Q) examination.

Alberta Apprenticeship Transfer Opportunity

A transfer agreement exists between graduates of the MTIM program and the Alberta Apprenticeship and Industry Training Office. Non-registered apprentice graduates are required to challenge the first three exemption tests, complete the fourth period of in-school training, and then complete the required number of on-the-job training hours. Graduates seeking employment in other provinces must negotiate transfer agreements on an individual basis. All provinces require apprentices to pass the Certificate of Qualification test in order to be designated millwrights.

Co-op

About Co-op

Students in this program have the opportunity to gain valuable work experience by applying classroom learning during co-op experiences.

Learn more about co-op terms and the roles and responsibilities of students and co-op advisors.

Program Capabilities

Program Capabilities outline what skills students should possess as they progress through each term/year of their program.

Students and employers will find this information most useful and can reference either the list of skills or the full program capabilities document to ensure students are gaining the experience they need to fulfill the program requirements.

More Information

Technology Requirements

It is recommended that students purchase a laptop with a Windows operating system.

Internet Speed Requirements

For best performance for students learning remotely, an internet connection with a minimum of 40 Mbps download and 10 Mbps upload speed is recommended in order to effectively use video conferencing and remote lecture delivery software as well as, other online resources remotely. Due to the large area over which students may be dispersed, we are unable to recommend a specific provider, so you will need to inquire around your area to find one that best suits your needs.

Minimum Laptop Requirements

In order to access the internet and virtually-delivered software and courseware, student laptops should include the following at a minimum. By meeting the following specifications, students will be equipped to access software and courseware on their laptop through the internet:

- Intel i5 8th Gen Processor or equivalent

- 16 GB of RAM (with a minimum of 8 GB)

- 100 GB HDD or more

- HD Graphics

- Webcam with a microphone

- Wireless 802.11n/ac 5ghz capable

- Windows Operating System (Windows 11)

Please note that Chromebooks and MacBooks may not support all software required for your program; students should verify compatibility with their professors.

Software

To ensure students are getting the most our of their classroom experience, some software will be required.

Lambton College has made this software easily accessible online. Students can leverage our Microsoft Office 365 software packages and services. In addition, much of the software you require for your courses will be available on demand for use on any device - on or off campus.