Automation and Instrumentation Technology

Overview

Mesh your hands-on skills and your love for technology and discover the limitless opportunities within the field of automation and instrumentation.

Students who enjoy hands-on automation and process control will appreciate the strong training and technical foundational provided in the Automation and Instrumentation Technology program.

Instrumentation, final control elements and process computer control systems in any manufacturing process environment are broken down into sequential logical steps, analyzed, and control is implemented. In industry, measured variables are then monitored and controlled. Examples of these variables include pressure, flow, temperature, level, motion, force, and chemical composition.

Topics of study include signal conditioning, transmitters, analyzers, controllers, control systems, and final control elements such as control valves, dampers, and electric motors. These are components of automated control loops. Typical process industries that utilize this technology include petrochemical, pharmaceutical, food processing, pulp and paper, automotive, and mining. Alongside the maintenance requirements of these industries there are other career options available including engineering, sales, and service providers or maintainers.

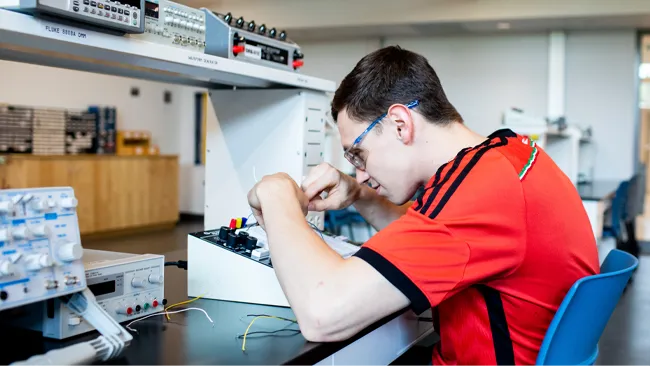

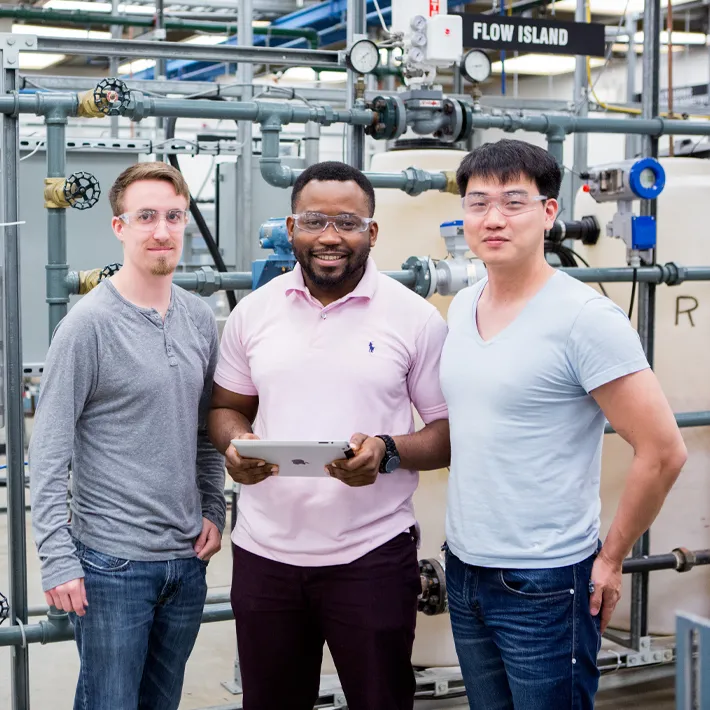

Students enrolled in this program train in the Centre of Excellence in Energy & Bio-Industrial Technologies. This centre offers state-of-practice technology laboratories and infrastructure to support learning and research in next-generation technologies in collaboration with industry. Numerous hands-on labs are designed to enable participants to install, configure, calibrate, troubleshoot, and maintain instruments (pneumatic, analog, digital) and control systems in a variety of industrial-replicated settings.

.

Let Andrew show you what it is like to be a student in the Instrumentation program.

Admission Requirements

O.S.S.D. or equivalent with:

- Grade 12 English C or U

- Grade 12 Mathematics C or U

Grade 12 Mathematics Requirement & Recommendations

Grade 12 Foundations for College Mathematics (MAP4C) minimum final grade is 60%. If the program is highly competitive, students with Grade 12 Mathematics for College Technology or any Grade 12U mathematics will be given preference. The following courses are also strongly recommended:

- Grade 11 Physics (SPH3U)

- Grade 12 Physics (SPH4U)

- Grade 12 Calculus (MCV4U)

Mature Student Assessment for this program is available in the subject of English for the purpose of demonstrating proficiency in this required admission subject. For all other admission requirements, applicants must complete the required course(s) as listed above. For more information, please contact counselling@lambtoncollege.ca. Review the Mature Student Admission process.

Academic admission requirements can be obtained through Academic Upgrading and the Pre-Technology & Trades (PTEC) program at Lambton College.

Ben's Story

'The ICET program at Lambton College has been an invaluable experience, providing me with cutting-edge industry knowledge, hands-on practical training, and a supportive learning environment, all of which have significantly enhanced my career prospects and personal growth."

Costs

- Year 1 $5,262.32

- Year 2 $5,180.32

- Year 3 $2,786.68

- Final Term $2,829.49

Please Note: These fees apply to the 2024-2025 academic year and are subject to change. Fees do not include books (unless specifically noted), supplies or living costs.

Additional Fees

-

Lab Coat$40.00

-

Calculator$40.00

-

Safety Shoes$150.00

-

Safety Glasses$20.00

Scholarships Available

There are 17 scholarships available for this program, with a total value of $21,850!

Technology Requirements

In order to keep pace with the requirements of each and every course in your program, Lambton College requires that each student have access to a laptop while studying at our college.

Labs & Equipment

Courses

Critical Thinking & Writing

In this writing course, students respond to current issues and news articles via various styles of paragraphs and essays. Students practice thinking critically and organize and hone their writing to ensure clarity and correctness in their messages. Students explore different perspectives, and through synthesis, analysis, and response, strive for clarity of message and diplomatic expression of opinion based on fact. One of the pillars of Lambton College is a commitment to sustainability and equity, diversity, and inclusion, including Indigenization of the curriculum; where appropriate, readings in this course will reflect this commitment. Critical Thinking and Writing lays the foundation for a subsequent research-writing course.

Electric Circuits I

This is an introductory course in electricity consisting of fundamental electric principles together with an analysis of simple electric circuits. Emphasis throughout the course is on problem solving. Laboratory exercises complement the material covered in class.

Fundamentals of Instrumentation I

This is an introductory course in process instrumentation and safety. Topics will include WHIMS and an introduction to industrial hazards, Job Safety Analysis, and Work Permits. Basic instrumentation and control loop concepts, instrument signalling, wiring, and calibration techniques will be studied. Pressure measurement will be covered in greater detail. The reading and interpretation of Process and Instrumentation Diagrams will be addressed. The laboratory component will expose the student to the correct use and operation of calibration devices, pressure sensors and measuring instruments.

Mathematics for Technology I

This course reviews and develops concepts in algebra, trigonometry, complex numbers, and vectors with technical applications.

General Education Elective

General Education Elective

Communications for Technology II

Technical writing differs from most student writing; therefore, it is necessary for students to learn the structure, nuances, and style of technical writing to be successful in completing labs, summaries, and reports. Through research writing and documentation, and through oral presentations, successful students will gain important transferrable skills that provide the basis for technical communication required in their other coursework and the workplace.

Electric Circuits II

This course is designed to extend the student's knowledge and experience in the areas of DC network theorems and alternating current RC, and LCR networks. Emphasis throughout the course is on problem solving. These concepts are supported and reinforced in the laboratory portion of the course.

Introduction to CAD for Instrumentation & Control

This is an introductory course on the use of AutoCAD 2019 Computer Assisted Design and Drafting software. Students learn to access AutoCAD commands for preferences, drawings modifying, dimensioning, applying text and plotting, to produce 2-D drawings. The use of Computer Assisted Design as a drafting and design tool that is used extensively in many industries locally and throughout the world. An individual who learns understands and can apply this program, has little difficulty transferring those skills to other CAD programs. AutoCAD is introduced as a valuable tool that could be used by any technologist, with a focus on electrical, process control and instrumentation.

Fundamentals of Instrumentation II

This course consists of an introduction to some of the fundamentals of process variables such as temperature, pressure, and level measuring instruments. Topics include primary sensing devices, terminology and symbols, and test equipment usage including calibration procedures. The laboratory portion of the course allows the student to become familiar with various types of test equipment, connection of instruments to sense process variation, apply calibration standards, and learn troubleshooting skills.

Mathematics for Technology II

This course contains elements of algebra, and introduces the concept of functions including graphing. It also introduces differential and integral calculus with basic applications.

Physics

An introductory course in physics covering mechanics and heat. This course consists of six units of theory and six laboratory assignments. The theory unit topics are measurements; motion; fluids; heat energy; force; and work, energy and power. The laboratory component provides the learners with hands-on experience in exercises, which complement the lecture material.

Electronic Devices & Circuits I

This course, intended for Instrumentation and Control Engineering Technology students, investigates the characteristics, basic circuits, and biasing techniques of semiconductor diodes, transistors, thyristors, and linear integrated circuits. Operational amplifiers are examined and various applications of Op-Amps to instrumentation and control are explored. The student's knowledge and understanding of electric circuits will grow through the use of lectures and labs.

Process Instrumentation I

This is an intermediate level course in Instrumentation for those going into the field of Instrumentation & Control. Students will develop an understanding of Instrumentation terminology, symbology, and elements of Instrument systems. Methods of flow measurement and installation aspects of devices will be covered in detail. Final control elements such as solenoids, electric motors, and control valves will be covered in detail. The laboratory portion of the course allows the student to become familiar with various types of test equipment, connection of instruments to sense process variation, apply calibration standards and learn troubleshooting skills.

Job Search & Success

This course provides student with skills and knowledge to help support their career search and succeed in the workplace. Students align their personal skill set and goals to guide them on their career paths. They will learn how to effectively conduct a job search, build a professional and well-tailored resume and cover letter, and develop and practice interview techniques. Students will also develop their personal brand to help support effective career networking and aid in their job search. Teamwork and collaboration in the workplace are also discussed. Self-reflection is used to inspire insight and support their professional career journey.

Mathematics for Technology III

This course is a continuation of differential and integral calculus, including trigonometric, logarithmic and exponential functions. The course also contains partial differentiation, methods of integration, and advanced applications of derivatives and integrals.

Statistics for Technology

This course contains descriptive statistics, basic probability, and regression analysis. The course also includes binomial distribution, normal distribution, Student's t-distribution and F-distribution. The statistical ideas of sampling, confidence intervals, and hypothesis testing are introduced. This course also includes elements statistical process control, and system reliability.

General Education Elective

Digital Logic

This course is designed to give technology students a thorough understanding of digital techniques and logic circuits, as applied to Industrial Control Circuits and to Processor Based Control Systems. Theory is presented in a two-hour weekly lecture schedule supported and supplemented by a two-hour weekly laboratory, which is designed to reinforce the lecture materials. The foundation of the course begins with a study of digital logic gates and functions and expands to include combinational and sequential logic, culminating with a study of the architecture and functioning of microprocessor based systems such as computers, programmable logic controllers (PLCs) and industrial control systems.

Electrical Systems & Control

This course is designed to extend the student's knowledge and experience into the areas of single-phase and balanced three-phase alternating current systems. The terminal properties of AC and DC motors, generators and transformers are thoroughly investigated, and the student is introduced to the control strategies and devices most commonly used with these machines. Emphasis throughout the course is on problem solving. These concepts are supported and reinforced in the laboratory portion of the course.

Microcontrollers & Sustainable Systems

This course is a continuation of ICS-3305. Topics will include: principles of measurement of additional process variables such as weight, density, and humidity; control valve technologies; panel instruments; sizing and application of control valves; instrument air systems; hazardous area classifications; electrical wiring practices and interpretation of loop wiring diagrams; overview of digital communications network structures and protocols; and an introduction to fiber optics technology. A series of laboratory experiments will illustrate the measurement principles, calibration and installation techniques for a variety of sensors and control valves.

Programmable Logic Controllers I

Mathematics for Technology IV

This course contains the analysis and applications of arithmetic, geometric, and power (Maclaurin and Taylor) series as well as the construction and application of trigonometric (Fourier) series. Methods of solving first and second order differential equations are introduced, including the use of Laplace transform.

Co-op Work Term (Four Months)

Co-operative education provides students with the opportunity to apply classroom learning to the workplace, undertake career sampling and gain valuable work experience that may assist students in leveraging employment after graduation.

Co-op Work Term (Four Months)

Co-operative education provides students with the opportunity to apply classroom learning to the workplace, undertake career sampling and gain valuable work experience that may assist students in leveraging employment after graduation.

Process Instrumentation Projcet Management & Documentation

Process Control Systems

This course consists of an introduction to process control and control systems. Topics include process characteristics, Proportional-Integral-Derivative(PID) modes of control, On/Off control, PID tuning, batch/continuous control, multivariable control and non-linear control. Applications are presented in each case. The laboratory portion of the course allows the student to operate many types of single loop and multi-loop control systems, with the primary emphasis on controller tuning.

Programmable Logic Control II

An integrated lecture/laboratory course where learners are introduced to the fundamentals of programmable logic control design. Applications of programmable logic controllers are stressed. This course will allow the learner to study control systems which use discrete components and continuous/analog systems operated in well defined sequential steps to bring about a desired result. Using the unique control features afforded by PLC's, and by judicious application of PLC fundamentals, the learner will also demonstrate an ability to bring process systems under control.

Process Analyzer Systems

This course is a study of industrial, continuous operation process stream analyzers that measure process conditions directly. The course focuses on analyzer theory of operation, application, installation, programming and calibration of on-line analyzers. Analyzers studied include gas chromatographs, pH, electrolytic conductivity, IR, oxygen, gas detectors as well as process stream sample systems. These analyzers monitor feedstock and product composition and quality, give insight into process efficiency, and are often the first line of defence for worker health and safety and environmental protection. This course will also give insight into their use for closed loop process control.

Systems Automation I

This course is an introduction to automation systems and robotics technology. Canada's robotics safety code will be examined and interpreted. Automation hardware components such as industrial robotic arms, tooling, controllers, teach pendants, industrial sensors, vision systems, conveyors and safety systems will be utilized. The programming of industrial robots to efficiently accomplish assignment objectives is an integral part of the course. Hands on lab exercises will permit students to illustrate their knowledge and competency in achieving a reliable solution to various automation objectives.

Co-op Work Term (Four Months)

Co-operative education provides students with the opportunity to apply classroom learning to the workplace, undertake career sampling and gain valuable work experience that may assist students in leveraging employment after graduation.

Electrical Systems & Controls II

This is an introductory course in the study of electric power generation, transmission, distribution and utilization as it applies in industrial, commercial and residential settings. Students will learn about single-phase and three-phase systems, emphasizing the study of voltage drops and fault current analysis leading to calculation of cable and conductor sizing and specification of coordinated protective device systems. This is a hybrid course which combines weekly two-hour lectures with two-hour labs. The lab sessions support and reinforce the lectures and are conducted in a dedicated lab which includes an integrated voltage, current and power monitoring system with a data acquisition and display system. The students will extend their knowledge through additional on-line learning assignments.

Advanced Process Control

This course is a continuation of ICS5306. Students will study advanced aspects of process control including: use of distributed control systems; feedforward control; multi-loop control; process control applications for chemical process unit operations such as distillation, steam generation (boiler) etc. The laboratory component will require students to design and configure control systems using the distributed control systems located in the college's pilot plant facilities.

Instrumentation & Control Capstone Project

A capstone course provides an opportunity for students to demonstrate all that has been learned during their studies and co-op work experience. Capstone experiences are superior examples of engagement through the integration of learning, knowledge, and application. This course provide the opportunity, space and resources for the instrumentation and control engineering technology students to innovate and create engineering projects that address today's automation and manufacturing challenges. Student will develop ideas into workable engineering projects, create a project statement of work that identify deliverables, needed resources, and milestones. In addition, they will provide complete design concepts with the appropriate documentation; flow diagram, instrument loops, technical drawings, installation procedures and operational manuals. Students will learn to work within the scope of the applicable codes and standards needed to implement a functional engineering system.

Systems Automation II

Control Systems Architecture & Data Communication

This course is an introduction to industrial process control systems, hardware architecture, and industrial data communications. Techniques and tools utilized for troubleshooting process control loop problems, and data communication systems are examined. The need for Instrumented Safety Systems is investigated and various system architectures are examined and evaluated using traditional qualitative and quantitative analysis techniques. Laboratory exercise involve the programming of traditional operator interfaces, implementing, integrating, and troubleshooting industrial communication systems, safety instrumented systems, and processes.

Contact

Program Information

Applied Science, Engineering Technology & Trades

After Graduation

Employment Opportunities

Our graduates find employment in a wide variety of areas in the instrumentation and control field. Technologist opportunities for employment exist in the chemical, petroleum refining, food processing, automotive manufacturing, steel production, and pulp and paper industries. Typical positions include: process analyzer specialist, instrument designer, control systems technologist, instrument technologist, instrument technician, and process control.

Accreditations & Certifications

Canadian Armed Forces

This program is recognized by the Canadian Armed Forces for the Weapons Engineering Technician training requirement. ICET graduates are eligible for 750 hours (52%) of training avoidance.

Weapons Engineering Technicians are responsible for the corrective and planned maintenance activities of the weapons on board a ship.

Pathways

Transfer to Programs within Ontario

- Bachelor of Technology Partnership: Combined Degree/Diploma - enter third year of four-year program

Want to see more Ontario transfers? Visit ONTransfer.ca.

Transfer to Programs outside of Ontario

Co-op

About Co-op

Students in this program have the opportunity to gain valuable work experience by applying classroom learning during co-op experiences.

Learn more about co-op terms and the roles and responsibilities of students and co-op advisors.

More Information

Pathway to Apprenticeship

Graduates of Lambton College's Instrumentation & Control Engineering Technology - Industrial Automation program now have a pathway to pursue apprenticeship after graduation.

Lambton College is approved by the Ministry of Training, Colleges and Universities to offer a unique diploma-to-apprenticeship pathway that would exempt graduates of this program from all levels of the ICT-447A apprenticeship.

Technology Requirements

It is recommended that students purchase a laptop with a Windows operating system.

Internet Speed Requirements

For best performance for students learning remotely, an internet connection with a minimum of 40 Mbps download and 10 Mbps upload speed is recommended in order to effectively use video conferencing and remote lecture delivery software as well as, other online resources remotely. Due to the large area over which students may be dispersed, we are unable to recommend a specific provider, so you will need to inquire around your area to find one that best suits your needs.

Minimum Laptop Requirements

In order to access the internet and virtually-delivered software and courseware, student laptops should include the following at a minimum. By meeting the following specifications, students will be equipped to access software and courseware on their laptop through the internet:

- Intel i5 8th Gen Processor or equivalent

- 16 GB of RAM (with a minimum of 8 GB)

- 100 GB HDD or more

- HD Graphics

- Webcam with a microphone

- Wireless 802.11n/ac 5ghz capable

- Windows Operating System (Windows 11)

Please note that Chromebooks and MacBooks may not support all software required for your program; students should verify compatibility with their professors.

Software

To ensure students are getting the most our of their classroom experience, some software will be required.

Lambton College has made this software easily accessible online. Students can leverage our Microsoft Office 365 software packages and services. In addition, much of the software you require for your courses will be available on demand for use on any device - on or off campus.

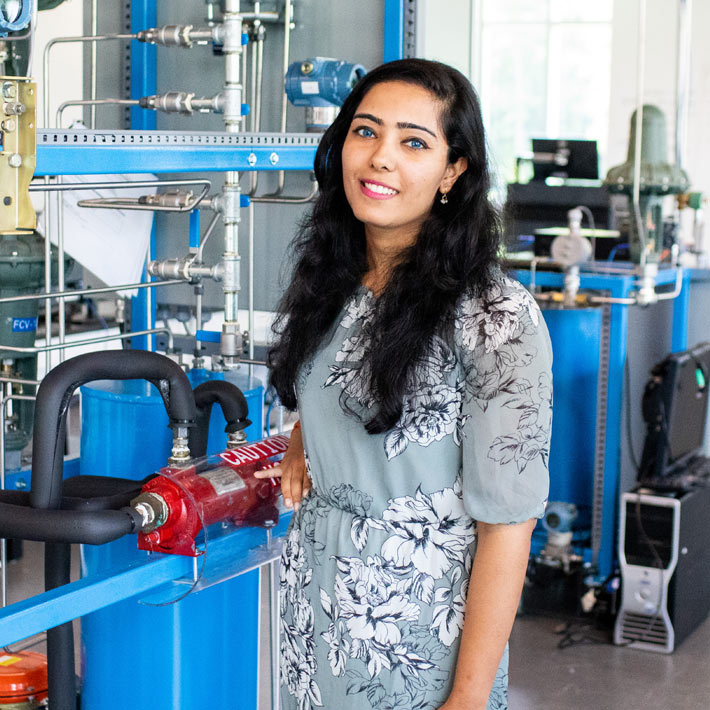

Women in Technology & Trades

Discover how Lambton College's Women in Technology & Trades (WiTT) group is empowering women to excel in technology and trades.

Visit our WiTT page for more information on mentorship opportunities, events, and resources designed to support your journey in these dynamic fields.

Learn More

Sample Robotics Assignments

View this selection of videos that showcase robotics assignments that were programmed by Instrumentation students in the third year of their program.