Power Engineering Technology

Overview

Aim for a career that can take you anywhere in Canada with the Power Engineering Technology program and discover the wide array of career options available to our graduates.

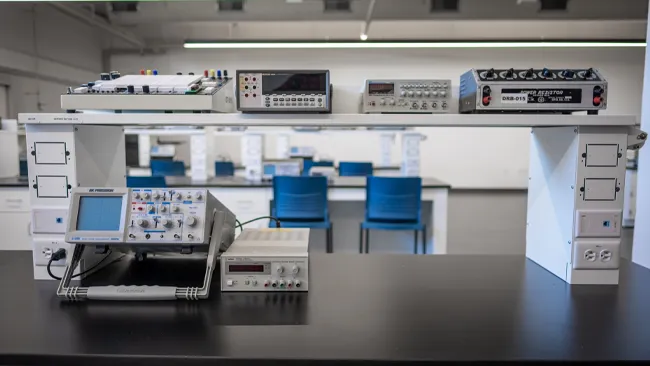

Throughout Canada only certified Power Engineers are permitted to operate, maintain and manage equipment such as boilers, compressors, turbines and refrigeration units. Lambton College's newly renovated closed loop 107 KW power generation plant operates exclusively as a training facility and is located in Centre of Excellence in Energy & Bio-Industrial Technologies. This is the only training unit of its kind in Ontario and students work collaboratively to generate and operate the power plant. In addition, the Centre also offers many other state of practice laboratories including distillation pilot plants, water treatment facilities, computer simulators, electrical and control systems and much more.

You will gain knowledge and skills of plant operations and maintenance focusing on the 4th Class level in year one, the 3rd Class level in year two, and the 2nd Class level in the final year.

There are 4 different levels of Operating Engineer status granted by the Technical Standards and Safety Authority (TSSA), each level involving more complex tasks which qualify individuals for higher level employment. Lambton College's Power Engineering Technology program follows the curriculum of the standardized Power Engineer's examination committee (SOPEEC) and prepares students to write the TSSA examinations for 4th, 3rd and 2nd class certification.

2nd Class Power Engineering certification is the highest level of power engineering training within the Ontario College system ensuring that Lambton College's Power Engineering Technology program offers employers highly trained and skilled graduates. Importantly, successful completion of our unique curriculum will allow students to qualify for Qualifying Experience Time reduction.

Women in Technology & Trades

Discover how Lambton College's Women in Technology & Trades (WiTT) group is empowering women to excel in technology and trades.

Visit our WiTT page for more information on mentorship opportunities, events, and resources designed to support your journey in these dynamic fields.

Learn More

Admission Requirements

O.S.S.D. or equivalent with:

- Grade 12 English C or U

- Grade 12 Mathematics C or U

- Grade 11 or 12 Chemistry C or U

-or-

Grade 11 or 12 Physics C or U

(both recommended, only one required)

Grade 12 Mathematics Requirement

Grade 12 Mathematics for College Technology or any grade 12U mathematics is recommended; Grade 12 Foundations for College Mathematics (MAP4C) minimum final grade is 60%. If the program is highly competitive, students with Grade 12 Mathematics for College Technology or any Grade 12U mathematics will be given preference.

Mature Student Assessment for this program is available in the subject of English for the purpose of demonstrating proficiency in this required admission subject. For all other admission requirements, applicants must complete the required course(s) as listed above. For more information, please contact counselling@lambtoncollege.ca. Review the Mature Student Admission process.

Academic admission requirements can be obtained through Academic Upgrading and the Pre-Technology & Trades (PTEC) program at Lambton College.

Fun Facts

- The Institute of Power Engineers (IPE) reports that an entry level power engineer (4th Class) can expect to make $25 - $30 per hour.

- Top 1st Class Engineers can make upwards of $200,000 after years or even decades of training and experience.

Costs

- Year 1 $6,666.90

- Year 2 $6,584.90

- Year 3 $6,483.94

Please Note: These fees apply to the 2024-2025 academic year and are subject to change. Fees do not include books (unless specifically noted), supplies or living costs.

Additional Fees

-

Lab Coat$40.00

-

Calculator$40.00

-

Safety Shoes$150.00

-

Safety Glasses$20.00

-

4th Class Power Engineering Textbooks$1,250.00

-

3rd Class Power Engineering Textbooks$1,298.00

Scholarships Available

There are 13 scholarships available for this program, with a total value of $12,250!

Technology Requirements

In order to keep pace with the requirements of each and every course in your program, Lambton College requires that each student have access to a laptop while studying at our college.

Courses

Chemistry for Power Engineers

This course introduces students to relevant chemical aspects. It includes a review of fundamental chemical principles including atomic structure,chemical bonding and stoichiometry. Based on these foundations, the course focuses on developing an understanding of aqueous solutions and the treatment of water and wastewater. The course is delivered as two lecture hours per week and an associated two-hour biweekly lab. The laboratory portion applies theoretical concepts to a selection of physicochemical processes and allows students to develop skills of careful manipulation and observation.

Critical Thinking & Writing

In this writing course, students respond to current issues and news articles via various styles of paragraphs and essays. Students practice thinking critically and organize and hone their writing to ensure clarity and correctness in their messages. Students explore different perspectives, and through synthesis, analysis, and response, strive for clarity of message and diplomatic expression of opinion based on fact. One of the pillars of Lambton College is a commitment to sustainability and equity, diversity, and inclusion, including Indigenization of the curriculum; where appropriate, readings in this course will reflect this commitment. Critical Thinking and Writing lays the foundation for a subsequent research-writing course.

Instrumentation for Power Engineers

This is an introductory course in instrumentation for those going into the power engineering fields. Students will develop an understanding of instrumentation terminology, symbology, and elements of instrument systems. Methods of measurement devices for pressure, level, flow, and temperature measurement will be covered in detail. Boiler instrumentation and introductory controls are highlighted for the Operating Engineering curriculum. A series of laboratory experiments will illustrate the operation of conventional and smart field instrumentation.

Mathematics for Technology I

This course reviews and develops concepts in algebra, trigonometry, complex numbers, and vectors with technical applications.

Operating Engineering Studies I

This is an introductory course in Operating Engineering, which will give a general overview of process equipment, systems, and techniques. The codes and regulations that apply to Operating Engineering will be discussed. Emphasis will be placed on safety concerns such as WHMIS, plant safety, protective equipment, fire protection and extinguishing equipment, and environmental impacts. Process drawing fundamentals, basic process equipment such as steam traps, relief valves, piping systems, and lubrication systems will be studied.

Operating Engineering Calculations

This course aims to provide students of engineering technology disciplines with a solid foundation in mechanics for process operation and thermodynamics for steam plant operation, to the level required for 4th Class Operating Engineer Certification by Technical Standards and Safety Authority. The emphasis is on the understanding of the theory and applying it to solve practical problems of processes and plant.

Health & Safety for Industrial Processes

The graduate of this course will have a good understanding of safety aspects of the law, the legal responsibilities of the workplace, and his/her own legal rights and responsibilities, as well as work processes and procedures being used in present-day industry. This course will give them a basic understanding of the Occupational Health and Safety Act and its associated Regulations, and an understanding of health and safety issues in an industrial setting.

Job Search & Success

This course provides student with skills and knowledge to help support their career search and succeed in the workplace. Students align their personal skill set and goals to guide them on their career paths. They will learn how to effectively conduct a job search, build a professional and well-tailored resume and cover letter, and develop and practice interview techniques. Students will also develop their personal brand to help support effective career networking and aid in their job search. Teamwork and collaboration in the workplace are also discussed. Self-reflection is used to inspire insight and support their professional career journey.

Power Plant Maintenance

Students will gain knowledge of application of common hand tools, mechanical fasteners, hoisting equipment and power tools. There will be opportunity to work in the shop to gain practical experience with related tools and equipment. Equipment applied for hands-on experience includes pumps, compressors, and piping.

Operating Engineering Studies - Boilers

This course covers theoretical knowledge required to understand the systems, processes, and operation of various types of power plants, and helps prepares the student for the Power Engineering Certification Examinations. Topics covered include combustion, piping, types of plants, instrumentation, boiler construction, parts and fittings, boiler operation and control, including legislation and regulations.

Operating Engineering Studies - HVAC

This course focuses on heating, ventilation, air conditioning systems, and building services. Low pressure steam and hot water heating systems, including their operations, controls, and basic maintenance, are explored. Various HVAC layouts are examined, as well as humidification systems, heat recovery, and heat gain/loss by buildings. An introduction to building lighting, water, and sanitary sewer systems is included.

Refrigeration Theory & Systems I

This course covers the thermodynamics of refrigeration systems, classes of refrigerants and a thorough understanding of both vapour compression and absorption refrigeration systems. Compressors and heat transfer equipment as applied to refrigeration systems are covered. The operation, safety, controls, and maintenance of these systems are included, and applied to refrigeration trainer systems on site.

Operating Engineering Studies - Equipment

Operating equipment pertaining to various types of Industries will be discussed throughout this course. It offers a practical approach to pumps, air compressors, steam turbines and engines, gas turbines, and internal combustions engines. Their principles of operation, classifications, components, basic maintenance and troubleshooting will be explored and investigated through both theory and hands-on applications. This course also offers an overview of an array of process systems, such as flares and different utility systems, which rely on industrial equipment to operate.

General Education Elective

Co-op

Co-operative education provides students with the opportunity to apply classroom learning to the workplace, undertake career sampling and gain valuable work experience that may assist students in leveraging employment after graduation.

3rd Class Power Engineering A

Topics included in this course will coincide with other term courses to provide the complete picture of the 3rd Class curriculum. This includes 3rd Class basic chemistry, metallurgy and materials, Cogeneration, Wastewater treatment, and the study of fuels and combustion technology. Industrial safety and fire protection will also be reinforced.

Electro-Technology for Power Engineers

Students will study electrical technology, machines, and control systems as applicable to the 3rd Class power engineering requirements. AC and DC theory, magnetism, and application to motors and generators will be covered, as well as systems and switchgear. Electrical calculations related to this discipline are included. In addition, students will study pneumatic, electrical, and digital control loops and control schemes including and introduction to programmable logic controls and data acquisition systems.

Piping & Mechanical Systems

This is an advanced level course in materials and mechanical systems. Metals and non-metals materials are studied and the science of corrosion, including protection methods. Piping and pressure vessel materials, codes and calculations, connections, supports and insulation designs and methods are covered. A study of steam traps and piping systems to reduce water hammer is made. Welding processes, techniques, certification and testing are studied.

High Pressure Boilers & Auxilarie

This is a 3rd class level course in boiler operation, control, and basic maintenance of packaged boilers and high pressure boiler systems. A thorough understanding of the codes and standards pertaining to boilers will be gained. The various designs of boilers, ratings, internals, auxiliaries, and fittings are a part of this study, as well fuel systems, draft systems, internal water treatment and water pre-treatment. Operating experience will be gaining in our 3rd class boiler and steam turbine laboratory facility to reinforce this material.

Statistics for Technology

This course contains descriptive statistics, basic probability, regression analysis, and probability distributions, including the binomial distribution and normal distribution. The statistical ideas of sampling and confidence intervals are introduced, and applications of probability and statistics are studied, such as reliability and statistical process control.

General Education Elective

Communications for Technology II

Technical writing differs from most student writing; therefore, it is necessary for students to learn the structure, nuances, and style of technical writing to be successful in completing labs, summaries, and reports. Through research writing and documentation, and through oral presentations, successful students will gain important transferrable skills that provide the basis for technical communication required in their other coursework and the workplace.

Mathematics for Technology II

This course contains elements of algebra, and introduces the concept of functions including graphing. It also introduces differential and integral calculus with basic applications.

Operating Engineering Studies - Advanced Equipment

This course expands upon previous material to look in detail at pump theory including pump head calculations, pipe friction, net positive suction head, and pump sizing and installation considerations. Coverage of fluid statics and dynamics are integral to this fluids theory. Gas compressor theory of isothermal, polytropic, and adiabatic compression will be studied as well as the study of various types of compressors and control devices. Steam turbine systems and thermodynamics as well as gas turbine systems will be covered. Emphasis on heat exchangers and other common process equipment will be made so that the student has a deeper understanding of the theory and operation of most common process equipment.

Operating Engineering Calculations II

This course is to further develop the skills and knowledge in applied mechanics and applied thermodynamics obtained in OES-2123 (Operating Engineering Calculations I), which are of 4th class level of the Ontario Operating Engineer Certification. This course covers the advanced parts of applied mechanics, heat, thermal expansions and contractions, calorimetry, applied thermodynamics, and combustion, to the 3rd and 2nd class levels. Calculations are performed towards problem solving in these subject areas as preparation for higher level Operating Engineers examinations.

Refrigeration Theory & Systems II

This second refrigeration course reinforces and advances previous knowledge of vapour compression and absorption refrigeration by looking at higher levels of refrigeration concepts. An introduction to thermodynamic calculations related to gas compression and refrigeration systems will also be addressed. The operation, maintenance and trouble shooting of refrigeration systems are covered, along with an examination of refrigeration system measurement and control hardware and software. Refrigeration safety concerns and regulations will also be examined.

General Education Elective

Co-op

Co-operative education provides students with the opportunity to apply classroom learning to the workplace, undertake career sampling and gain valuable work experience that may assist students in leveraging employment after graduation.

Alternative Power Processes

This course is a study of electricity generation using renewable resources such as solar, wind, and biomass energy. Power Engineering Technology students need to be familiar with renewable electricity generation, as it is becoming more common due to environmental reasons and the available subsidies.

Plant Administration, Safety & Fire Protection

Topics of this plant management centered course include a management level understanding of legislation, codes and standards that affect the work place. Responsibilities and duties of all levels of engineers and managers in a production facility are emphasized. Also included are legislation and programs for safety in plants, a thorough understanding of fire protection systems, and plant engineering drawings. The course first examines various codes, regulations, acts and legislations from a safety and management perspective. Students then work towards a more complete understanding of industrial drawings and plant maintenance procedures. Also covered are typical requirements for emergency response and incident investigation and typical fire systems used in industrial plants.

Plant Administration & Applied Mechanics

The Plant Administration and Applied Mechanics course has been designed based on the SOPEEC syllabus to prepare students for TSSA exam 2A-1. The course aligns with the PanGlobal Power Engineering 2nd Class - A1 textbook and is designed so that students can complete the weekly readings and assignments around their work schedule. Topics of study include calculations of ASME vessel component thicknesses, reinforcement compensation of openings, firetube boiler components and stays. Applied Mechanics calculations are also covered in areas of statics and dynamics. Students must demonstrate a thorough knowledge of the Act and Regulations, and apply the knowledge to management principles for a typical plant including maintenance and safety administration. The final exam in this course is modelled on the format and question type of the SOPEEC exam to further help students prepare for the 2A-1 exam. This course is for 3rd Class Stationary Engineers preparing to take the TSSA 2nd Class Stationary Engineering Qualification. Students are responsible for ensuring they meet TSSA eligibility requirements for challenging the exam.

Advanced Thermodynamics & Material Science

The Advanced Thermodynamics and Material Science course has been designed based on the SOPEEC syllabus to prepare students for TSSA exam 2A-2. The course aligns with the PanGlobal Power Engineering 2nd Class - A2 textbook and is designed so that students can complete the weekly readings and assignments around their work schedule. Topics of study include calculations of thermal expansion in solids, liquids and gases. Gas laws and problems involving expansion or compression of gases are covered in detail. Thermodynamics of steam including entropy lead into calculations of steam cycles in a power plant setting. Heat engine cycles for various types of engines are detailed. Candidates will demonstrate a thorough understanding of material properties, composition, treatments and uses. Corrosion principles and control methods are covered. Mechanical testing of materials for both destructive and NDE methods are detailed. The course includes a final exam modelled on the format and question type of the SOPEEC exam to further help students prepare for the 2A-2 exam. This course is for 3rd Class Stationary Engineers preparing to take the TSSA 2nd Class Stationary Engineering Qualification. Students are responsible for ensuring they meet TSSA eligibility requirements for challenging the exam.

Advanced Boiler Systems & Pumps

The Advanced Boiler Systems and Pumps course has been designed based on the SOPEEC syllabus to prepare students for TSSA exam 2A-3. The course aligns with the PanGlobal Power Engineering 2nd Class - A3 textbook and is designed so that students can complete the weekly readings and assignments around their work schedule. Topics of study include an advanced study of steam generator design, applications, installation, and components. Advanced operations including water treatment and maintenance procedures are emphasized. A more detailed investigation of pumps included theory, and control methodology is also covered. The course includes a final exam modelled on the format and question type of the SOPEEC exam to further help students prepare for the 2A-3 exam. This course is for 3rd Class Stationary Engineers preparing to take the TSSA 2nd Class Stationary Engineering Qualification. Students are responsible for ensuring they meet TSSA eligibility requirements for challenging the exam.

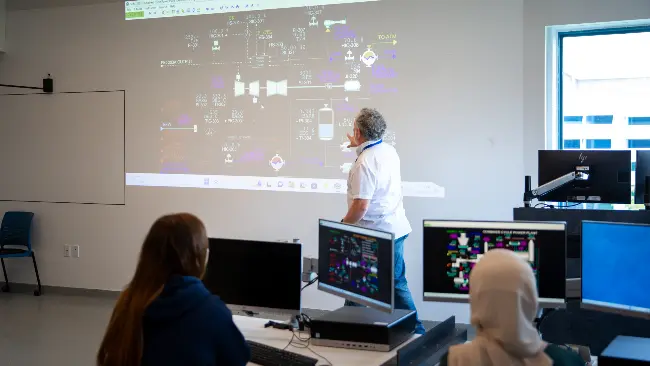

Advanced Power Plant Simulator

Students will study a Combined Cycle power plant simulation which includes a Gas Turbine & Generator, Heat Recovery Steam Generator (HRSG), three stage Steam Turbine & Generator, Condenser & Hot Well, Cooling Tower, and steam utility plant auxiliary equipment, through to the electrical power generation. Proper operating procedures are stressed, and the students are required to perform a full start-up and shutdown of the unit in a safe yet timely manner. The simulator allows for the introduction of process and equipment malfunctions that will require student response of appropriate nature.

Environmental Management

Leading-edge process operations are successful when the end product is produced safely and in an environmentally sound way. Modern technologists in the process industry are called on to carry out a wide range of tasks including environmental source control. This course is designed to develop a basic understanding of industrial process impact on environment, strategies of environmental protection as well as to appreciate responsibilities of process operators towards environment. The course emphasizes the importance of ecosystem concepts, societal demands, communication and environmental laws as they apply to chemical production facilities.

Heat Engine, Piping & Plant Documentation

The Heat Engines, Piping and Plant Documentation course has been designed based on the SOPEEC syllabus to prepare students for TSSA exam 2B-1. The course aligns with the PanGlobal Power Engineering 2nd Class - B1 textbook and is designed so that students can complete the weekly readings and assignments around their work schedule. Students are introduced to the theoretical principles, mechanical details, maintenance, lubrication and operation of various heat cycle engines including steam turbines, internal combustion engines, and gas turbines. A high level study of piping installations including code requirements is included. Students learn to interpret and comprehend the various types of plant drawings encountered including orthographic, P and IDs and flow diagrams, and other related documentation. The course includes a final exam modelled on the format and question type of the SOPEEC exam to further help students prepare for the 2B-1 exam. This course is for 3rd Class Stationary Engineers preparing to take the TSSA 2nd Class Stationary Engineering Qualification. Students are responsible for ensuring they meet TSSA eligibility requirements for challenging the exam.

Power Plan Systems, Combustion & Environment

The Power Plant Systems, Combustion and Environment course has been designed based on the SOPEEC syllabus to prepare students for TSSA exam 2B-2. The course aligns with the PanGlobal Power Engineering 2nd Class - B2 textbook and is designed so that students can complete the weekly readings and assignments around their work schedule. A complete overview of complex power plant systems is a major topic of study. A detailed look at plant instrumentation and control systems is studied. Detailed theory and controls of combustion systems for steam plants is included, with emphasis on environmental protection systems and operations requirement from air, water, and solids perspectives. The course includes a final exam modelled on the format and question type of the SOPEEC exam to further help students prepare for the 2B-2 exam. This course is for 3rd Class Stationary Engineers preparing to take the TSSA 2nd Class Stationary Engineering Qualification. Students are responsible for ensuring they meet TSSA eligibility requirements for challenging the exam.

Electro-Technology, Compression & Refrigeration

The Electrotechnology, Compression and Refrigeration course has been designed based on the SOPEEC syllabus to prepare students for TSSA exam 2B-3. The course aligns with the PanGlobal Power Engineering 2nd Class - B3 textbook. The course includes a more advanced study of the theory of operation of electrical machines and electrical distribution systems, leading into a detailed look at the construction and characteristics of AC and DC motors, generators, and other electrical equipment. The other major areas of study are principles, equipment and auxiliary systems with respect to gas compression systems and large scale refrigeration plants. Safety and code requirements are emphasized. The course includes a final exam modelled on the format and question type of the SOPEEC exam to further help students prepare for the 2B-3 exam. This course is for 3rd Class Stationary Engineers preparing to take the TSSA 2nd Class Stationary Engineering Qualification. Students are responsible for ensuring they meet TSSA eligibility requirements for challenging the exam.

Co-op Terms

Students are eligible to complete only one co-op and would select either Group A or Group B.

Contact

Program Information

Applied Science, Engineering Technology & Trades

After Graduation

Employment Opportunities

With fewer graduates than job vacancies in the industry there are positions available at every class level across Canada and the demand is only expected to increase.

Our graduates apply their skills to a wide variety of employment options in: electric power generation, chemical manufacturing, food processing, breweries, petroleum refining, pulp and paper, recreational facilities and institutions such as schools and hospitals. Power Engineers have the opportunity to increase their credentials throughout their careers, progressing all the way to 1st Class Power Engineers.

Accreditations & Certifications

Qualifying Experience Time (QET) Reduction

Qualifying Experience Time reduction decreases the time required working in industry to qualify for their Power Engineering certification. Students who successfully pass their 1st and 2nd term courses qualify for a nine-month QET reduction. Students who complete the 4th Class Power Engineering certification prior to the 3rd and 4th academic terms will qualify for 11 months of 3rd Class QET reduction.

Students who are successful in completing and obtaining their 3rd Class certification by term 5 will qualify for five months of QET reduction towards their 2nd Class certification after graduation. Successful completion of the PETC program along with the previously mentioned co-op will result in a reduction of 25 months of QET towards 2nd Class certification.

- TSSA 4th Class Certification Requirements

- TSSA administered 4A and 4B exams (requires additional fees paid by the student). The requisite amount of QET as defined by the TSSA.

- TSSA 3rd Class Certification Requirement

- 4th Class Stationary Engineering Certificate (see above) is required prior to the 3rd academic term to be eligible for 3rd class QET reduction. Successful completion of the TSSA 3rd Class exams. These are administered by the TSSA and require additional fees paid for by the student. The requisite amount of QET as defined by the TSSA.

- TSSA 2nd Class Certification Requirements

- 3rd Class Stationary Engineering Certificate (see above). Successful completion of the TSSA 2nd Class exams. These are administered by the TSSA and require additional fees paid for by the student. The requisite amount of QET as defined by the TSSA.

Power Engineering Technology and Chemical Production & Power Engineering Technology - Pathways

Co-op

About Co-op

Students in this program have the opportunity to gain valuable work experience by applying classroom learning during co-op experiences.

Learn more about co-op terms and the roles and responsibilities of students and co-op advisors.

Power Engineering Technology - Co-op Opportunities

More Information

Technology Requirements

It is recommended that students purchase a laptop with a Windows operating system.

Internet Speed Requirements

For best performance for students learning remotely, an internet connection with a minimum of 40 Mbps download and 10 Mbps upload speed is recommended in order to effectively use video conferencing and remote lecture delivery software as well as, other online resources remotely. Due to the large area over which students may be dispersed, we are unable to recommend a specific provider, so you will need to inquire around your area to find one that best suits your needs.

Minimum Laptop Requirements

In order to access the internet and virtually-delivered software and courseware, student laptops should include the following at a minimum. By meeting the following specifications, students will be equipped to access software and courseware on their laptop through the internet:

- Intel i5 8th Gen Processor or equivalent

- 16 GB of RAM (with a minimum of 8 GB)

- 100 GB HDD or more

- HD Graphics

- Webcam with a microphone

- Wireless 802.11n/ac 5ghz capable

- Windows Operating System (Windows 11)

Please note that Chromebooks and MacBooks may not support all software required for your program; students should verify compatibility with their professors.

Software

To ensure students are getting the most our of their classroom experience, some software will be required.

Lambton College has made this software easily accessible online. Students can leverage our Microsoft Office 365 software packages and services. In addition, much of the software you require for your courses will be available on demand for use on any device - on or off campus.