Electrician - Construction & Maintenance (309A)

An electrician plans, assembles, connects, installs, repairs, inspects, tests, verifies, and maintains electrical systems in various settings. Examples include residential, commercial, institutional and industrial. Electricians play a key role in protecting our environment by installing and maintaining green technology in new construction, retrofits, and commercial and industrial applications.

Lambton College offers the in-school portion of the curriculum set out by Skilled Trades Ontario.

Training

The Electrician apprenticeship program consists of on-the-job and in-school training. The program typically takes five years to complete and consists of:

- 8,160 hours of on-the-job training and work experience

- 840 hours of in-school training

Red Seal Exam

At the completion of the in-school portion of the apprenticeship, graduates are given a week of preparation before they write the Red Seal exam for the trade.

Our students may write this exam at the College at the end of the training, or book a separate time to write the exam at the MLTSD office.

What does an Electrician do?

Admission Requirements

To be eligible for this program, applicants must:

- Have a sponsor or employer and must be registered through the Ministry of Labour, Training & Skills Development

- Have a minimum Grade 12 high school education or equivalent

- Be at least 16 years of age

Application Process

This is an apprenticeship program and follows a different application process than regular post-secondary education programs. You cannot apply to this program through ontariocolleges.ca.

Applicants who are registered as an apprentice in a trade should receive a letter from the Ministry of Labour, Training & Skills Development inviting them to apply for schooling. All applications from that point will need their payment processed by the Office of the Registrar & Financial Aid Services at Lambton College.

If you are a registered apprentice and have not received a letter regarding apprenticeship school, please contact your local Ministry of Labour, Training & Skills Development office.

Training Dates

The following training dates are for the 2023-2024 academic year for the Construction Maintenance Electrician apprenticeship.

- Basic (CMEB) Dates

- November 11, 2024 - January 24, 2025

- Intermediate (CMEI) Dates

- August 26, 2024 - November 1, 2024

- Advanced (CMEA) Dates

- February 3, 2025 - April 18, 2025

Course List

Canadian Electrical Code

Through this course the apprentice gains working knowledge on how to apply the requirements of the Canadian Electrical Code - Part 1 to identify and interpret the general requirements of the Canadian Electrical Code; identify and interpret the Canadian Electrical Code requirements for conductor ampacity including free air, above and underground installations, grounding and bonding, wiring methods, class 1 and 2 circuits, receptacles and lighting in residential occupancies, single dwelling and dwelling units, pools, tubs and spas, and temporary installations; and be able to calculate the service requirements for a residential occupancy, single-dwelling and row housing.

Prints

Through this course the apprentice gains working knowledge on how to identify and interpret the alpha numerical lines; use the metric and imperial scales and be able to convert between them; obtain information from architectural, structural and mechanical drawings, specifications, building code and Canadian Electrical Code to complete an electrical installation for a single-dwelling; draw and label a panel schematic for a single-dwelling; and complete a material take-off for a single dwelling.

Electrical Theory

Through this course the apprentice gains the understanding of electron theory; define voltage, current and resistance, as well as electrical and mechanical power and energy; describe the effects of electricity on the human body; explain the principles of common sources of Electro-Motive Force; and to analyze series, parallel and combination Direct Current circuits by applying Ohm's Law and Kirchoff's Laws; describe magnetic lines of force and list their characteristics; describe the relationship between magnetism and Electro-Motive Force.

Installation Methods Practical

Through this course the apprentice gains the ability to demonstrate the operation of common hand and power tools; install common switching devices, outlets and enclosures; correctly terminate conductors; demonstrate the installation procedures for non-metallic sheathed cable, armoured cable, mineral insulated cable, rigid conduits, flexible conduits, liquid-tight conduit, electrical metallic tubing, and electrical non-metallic tubing, including supports and tools required; install a 100 amp. residential consumer's service and associated branch circuits; layout a service mast installation; install door, signal and extra-low voltage lighting devices; identify and terminate copper communication and hard wired cables.

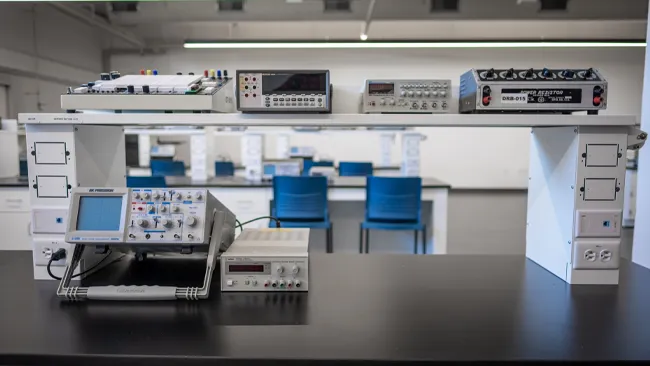

Instrumentation & Theory

The purpose of this course is to provide the apprentice with the ability to explain common terms used in instrumentation systems; work with the SI and Imperial system of measurement for pressure and temperature; convert between the four temperature scales; describe the operation, applications and limitations of thermocouples, thermistors, and RTD's; install, connect, and test thermocouples, thermistors, and RTD's; identify deformation elements of pressure measuring equipment; determine the accuracy of pressure measuring equipment; explain relationships between gauge and absolute pressure and vacuum; explain the operation, construction and applications of typical industrial pressure sensors; Identify ISA instrumentation symbols and draw basic process (P) and Instrumentation (I) diagrams for pressure and temperature devices; explain the operation of light and sound meters.

Electronics Theory & Practical

The purpose of this course is to provide the apprentice with the ability to identify schematic symbols of North American and European basic logic gates; describe the operation of basic logic gates; use basic logic gates to create digital logic circuits; state Boolean equations for simple logic gates; design and test combination logic circuits; describe the voltage requirements for ITL and CMOS logic circuits; demonstrate the use of R.S. and D type flip-flop; use a logic probe to troubleshoot a digital circuit, demonstrate procedures for soldering and de-soldering; state the standard resistor colour code; connect resistors in series, parallel and combination circuits; describe the properties of N and P type semiconductor materials; explain current, voltage and biasing requirements for silicon and germanium diodes, and LED's demonstrate the operation of a bipolar diode; identify the symbols for and describe the operation and biasing for NPN and PNP Bipolar transistors; demonstrate how a transistor can base used as a switch, demonstrate the common applications for an opto-coupler.

Canadian Electrical Code

The purpose of this course is to provide the apprentice with the ability to interpret the Canadian Electrical Code requirements pertaining to the installation for: interior and exterior lighting systems; fire alarms and fire pumps, emergency systems, unit equipment and exit signs; fuses, circuit breakers and ground fault protection and control devices; equipment in hazardous locations; hospitals and patient care areas; storage batteries; individual continuous and non-continuous duty service motors; and to calculate conductor and overcurrent device sizes required for specific continuous and non-continuous loads and the minimum ampacity of conductors and overcurrent devices for apartment and similar buildings.

Prints

The purpose of this course is to provide the apprentice with the ability to determine utility location and site features using site drawings; determine methods of construction using architectural and structural drawings; determine the electrical characteristics and layout of mechanical equipment and systems; lay out commercial distribution and service equipment and wiring; lay out branch circuit for lighting and equipment; prepare a material take off using drawings, specifications; prepare sketches to solve and document construction problems and solutions; prepare as-built drawings; and develop basic single line, schematic, and wiring diagrams.

Electrical Theory

The purpose of this course is to provide the apprentice with the ability to describe magnetic flux and flux density; solve problems associated with magnetic energy; explain Ohm's Law as applied to magnetic circuits; describe factors which affect inductance and perform related calculations; apply Fleming's hand rules and Lenz's law; describe the types, construction, operation and characteristics of DC machines; describe a sine wave; calculate RMS, average, maximum, and instantaneous values; calculate frequency, electrical and mechanical degrees; calculate phasors, vectors and vector diagrams; describe the effects of alternating voltage and current in a resistive device; calculate inductive reactance, voltage, current, and power of an inductive circuit; calculate capacitive reactance, voltage, current, power and phase relationships of a capacitive circuit; calculate values for RL/RC/RLC series and parallel circuits; and calculate resonant circuits.

Installation Methods

The purpose of this course is to provide the apprentice with the ability to identify the mechanical parts, windings and wiring connections of DC machines; demonstrate manual and magnetic demonstrate methods for forward-reverse control of motors; demonstrate reduced voltage starting techniques for DC motors; identify the mechanical parts, windings and wiring connections for a single- and three-phase squirrel cage induction AC motor (SCIM); demonstrate manual and magnetic across-the-line starting techniques for single- and three-phase squirrel cage motors; demonstrate methods for forward and reverse control of single- and three-phase squirrel cage motors; demonstrate the control of a Single Phase Capacitor Start Dual Voltage Motor with a reversing drum switch, manual starter and a reversing magnetic starter; state the procedures for installing and aligning belt driven motors; and calculate and connect single-phase, 3-wire transformer services.

Instrumentation

Through this course the apprentice gains the ability to: identify and describe the operation of various level and flow sensing instruments; draw basic process and instrument diagrams using standard ISA instrumentation symbols; explain the operation and applications of typical level and flow measurement devices and transmitters; demonstrate the hydrostatic pressure principle of liquid level measurement; predict with calculations the effect of liquids of different specific gravities on the system; demonstrate the use of the venturi and the orifice plate in flow measurement; and install, connect and test load cells in typical weight measurement applications.

Monitoring & Communcation Systems

Upon successful completion of Monitoring & Communication Systems - 2.07, the apprentice will have demonstrated the ability to: describe the operation, installation, testing and troubleshooting requirements for initiation, signal, ancillary and supervisory circuits and devices, in a single two stage fire alarm system using the NBC, CEC, ULC and manufacturer's documentation; describe the basic operation of wet and dry sprinkler systems; describe the fire suppression agents, components and systems used in fire suppression systems; describe the methods used to terminate and test fibre optic cables; demonstrate an understanding intrusion systems and devices; describe the wiring and operation of nurse call systems; demonstrate the wiring and operation of nurse call systems; layout and wire common paging and communications systems; describe the operation of institutional clock systems; and describe the operation and installation requirements for common home automation systems.

Electronics

The purpose of this course is to provide the apprentice with the ability to: use and oscilloscope to test circuits; explain the importance of isolation when using test equipment; describe and demonstrate half and full wave rectification; connect capacitors and inductors to filter a power supply output; demonstrate the use of a zener diode as a regulator; demonstrate the operation of an SCR; demonstrate the operation of a DIAC and TRIAC; demonstrate how a DIAC and RC network can be used to phase shift a TRIAC; describe the operation and applications of a pulse transformer; explain the operation of a field effect transistor (FET) and operational amp (Op Amp); calculate the expected gain of inverting and non-inverting Op-Amp circuits; and demonstrate the operation of an Op-Amp used as a comparator and an amplifier.

Canadian Electrical Code

Upon successful completion of this course, the apprentice is able to interpret the CEC requirements pertaining to the installations for two or more continuous and non-continuous duty service motor on a feeder or branch circuit, hermetic refrigerant motor compressor, power and distribution transformers on a feeder and branch circuit, welders on a feeder and branch circuit, capacitors on a feeder, branch circuit and motor branch circuit, high voltage installations, over-current device selection based on load, and interrupting ratings and coordination.

Prints, Construction & Maintenance Only

Through this course, the apprentice gains a working knowledge on how to: Obtain installation details for a construction project from a complete set of drawings and specifications. Develop complex, single-line, schematic and wiring diagrams. Layout single- and three-phase systems for feeder and branch circuits from utility supply to utilization points. Calculate pulling stresses on a conductor/cable. Layout the grounding and bonding requirements for high voltage indoor and outdoor substations and vaults. Identify precautions for installing stress cones. Describe the requirements for terminating shielded and concentric neutral high voltage cables. Describe the testing methods and safety requirements for testing high voltage cables.

Electrical Theory

This course builds on the learning from Basic and Intermediate Electrical Theory and studies the various types of three-phase connections commonly used in the electrical industry. Topics will include three-phase systems, transformers and various types of motors. Calculations will be made on three-phase wye and delta systems with RLC loads, correction of power factor, transformer unknown values, transformer losses and efficiency, short circuit current and various motor data. This course also includes the study of principles of operation, application, construction and the trouble shooting of three-phase alternators and three-phase induction motors.

Installation Methods

Through this course, the apprentice gains a working knowledge of how to: Test transformers to determine polarity, impedance, winding ratio and insulation resistance. Connect three-phase transformers in wye and delta configurations. Connect three-phase RLC loads to transformers in balanced and unbalanced configurations. Connect single- and three-phase auto transformers for reduced voltage motor starting. Identify the parts and connections for a three-phase wound rotor motor. Describe the effects of differing resistance in the rotor circuit of a wound rotor motor under varying loads. Connect a two-speed squirrel cage motor. State the functions and applications of a Programmable Logic Controller (PLC). Determine language and addressing requirements of a PLC. Demonstrate the programming of common relay instructions, timers, counters, mathematic functions and word comparisons on a PLC. Identify methods and hard wiring of PLCs to equipment. Demonstrate methods of testing PLC inputs and outputs and design programs to operate machines in a required manner using many of the internal functions of a PLC

Instrumentation

This is an advanced course in instrumentation with an emphasis on control. Topics will include on/off control, PID control, position measurement and control, transducers and control valves.

Electronics

This course covers the connection, application, testing, theory and operation of DC and AC variable frequency drives. In addition, subjects related to the application of these drives, including the operation and application of reactors, harmonics and encoders, will be discussed.

This Employment Ontario program is funded in part by the Government of Canada and the Government of Ontario.

Contact Us

Applied Science, Engineering Technology & Trades