An Industrial Mechanic Millwright works on industrial machinery, mechanical equipment and components, including mechanical pneumatic, hydraulic, fuel, lubrication, cooling and exhaust systems, and pumps, fans, tanks, conveyors, presses, generators and pneumatic and hydraulic controls.

Training

The Industrial Mechanic - Millwright apprenticeship program consists of on-the-job and in-school training. The program typically takes four years to complete and consists of:

- 7,280 hours of on-the-job training and work experience

- 720 hours of in-school training

Red Seal Exam

At the completion of the in-school portion of the apprenticeship, graduates are given a week of preparation before they write the Red Seal exam for the trade.

Our students may write this exam at the College at the end of the training, or book a separate time to write the exam at the MLTSD office.

What does an Millwright do?

Admission Requirements

To be eligible for this program, applicants must:

- Have a sponsor or employer and must be registered through the Ministry of Labour, Training & Skills Development

- Have a minimum Grade 12 high school education or equivalent

- Be at least 16 years of age

-or-

- Enter Apprenticeship Training through an Ontaion Youth Apprenticeship Program (OYAP) through a participating Ontario Secondary School

Application Process

This is an apprenticeship program and follows a different application process than regular post-secondary education programs. You cannot apply to this program through ontariocolleges.ca.

Applicants who are registered as an apprentice in a trade should receive a letter from the Ministry of Labour, Training & Skills Development inviting them to apply for schooling. All applications from that point will need their payment processed by the Office of the Registrar & Financial Aid Services at Lambton College.

If you are a registered apprentice and have not received a letter regarding apprenticeship school, please contact your local Ministry of Labour, Training & Skills Development office.

Training Dates

The following training dates are for the 2024-2025 academic year for the Industrial Mechanic - Millwright apprenticeship.

- Basic (IMMB) Dates

- September 9, 2024 - November 1, 2024

- Intermediate (IMMI) Dates

- TBD

- Advanced (IMMA) Dates

- January 6, 2025 - March 7, 2025

Course List

Workshop Practice I

This course equips students with essential knowledge and skills in safety regulations, including lock-out, isolation, confined space procedures, and hazard prevention, as well as the use of protective gear and emergency response. Students will learn the proper selection, use and maintenance of both cutting and non-cutting tools, gaining proficiency in handling various tools like wrenches, drills, and saws for machinery maintenance and component fabrication. The course also covers accurate measurement techniques using imperial and metric systems, teaching the use of tools such as calipers, micrometers, and gauges for precise measurement and alignment, ensuring safety and compliance in their trade practices.

Workshop Technology I

This course aims to develop the student's understanding of machining operations, focusing on the principles of cutting and the relationship between speeds and feeds. By the end of the course, students will be able to read and apply chart information to determine feed, speed, and specifications for various machining tasks, and perform necessary metric and imperial conversions. They will learn to apply trade-specific calculations and formulas to ensure compliance with engineering drawings and manufacturing requirements during setup, layout, alignment, and machining processes. Emphasis is placed on understanding and adhering to safety procedures, selecting the right tools for the job, and executing tasks with precision and accuracy.

Machine Technology I

This course provides a comprehensive understanding of both ferrous and non-ferrous metals, including their properties, the effects of temperature, and basic heat treatment processes. It covers the characteristics of various metals and alloys, such as tensile strength, malleability, and hardness, and explains the purpose of alloying elements like carbon and silicon in steel. The course also explores non-metallic materials, including rubber and plastic, and details methods for heat-treating metals, annealing and tempering. Additionally, it addresses the types, applications, and qualities of different fasteners and the procedures for securing machinery using bolts and anchors. The course covers friction theory, lubrication terminology, the types and applications of various lubricants, including oils and greases, and how to read and interpret lubrication charts.

Rigging & Hoisting

This course is designed to equip students with comprehensive knowledge and practical skills related to safe lifting, hoisting, and machine-moving operations. Students will be able to understand and adhere to all relevant safety protocols for these activities. They will learn to plan and execute lifts by utilizing appropriate sling angles, load charts, and workload limits while assessing the characteristics of the loads being lifted. Students will learn about the selection, inspection, and maintenance of various hoisting and rigging equipment, including ropes, slings, chains, and scaffolding. Students will gain an understanding of the principles and operation of different types of hoisting equipment, such as hoists and cranes, and will learn to use international hand signals, overhead crane signals, and radio communications to ensure safe hoisting operations

Welding & Fabrication I

In this introductory course, students will acquire essential knowledge and skills related to welding and fabrication. The curriculum focuses on foundational objectives, including how to set up and operate oxy-fuel welding and cutting equipment, how to apply brazing and soldering techniques, how to set up and operate shielded metal arc welding (SMAW) applications and cutting, forming and shaping materials according to specifications. Students will apply theoretical knowledge to practical scenarios, adhering to safety guidelines set by the Canadian Standards Association (CSA) and Lambton College. This includes using personal protective equipment and understanding individual and team safety protocols.

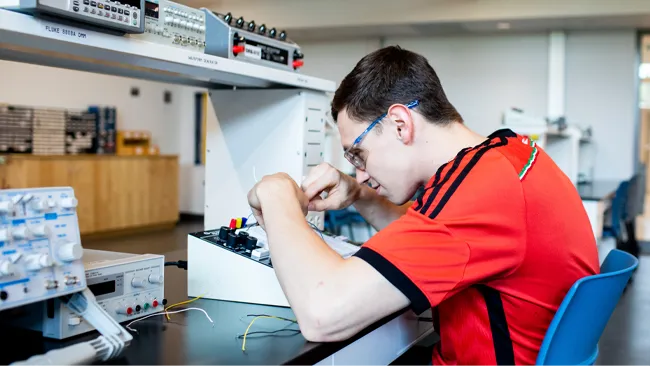

Electrical & Electronic Controls I

This course is designed to equip students with fundamental knowledge of electrical and electronic theory. It covers essential topics such as the purpose and scope of electrical codes, safety precautions, and the dangers of electric shock. Students will learn about the roles and functions of key electrical safety components, including fuses, circuit breakers, lock-outs, and tag-out procedures. Additionally, it includes an introduction to the design and characteristics of series and parallel circuits, along with their respective calculations. Students will select and use various electrical instruments like ohmmeters, continuity testers, ammeters, voltmeters, multimeters, and meggers.

Drawings & Schematics I

This course aims to equip students with the skills to effectively draw, sketch, and understand engineering drawings and schematics including orthographic and multi-view projections, as well as auxiliary views of machine components. This course also covers the fundamental principles of geometric tolerancing and the interpretation of related symbols.

Workshop Practice II

General Learning Outcomes To develop the apprentice's knowledge of the function, component parts, holding devices, accessories, cutting tools, and machining operations on the milling machine/surface grinder To develop the apprentice's knowledge to select, install, and maintain friction/plain and anti-friction bearings, and static and dynamic seals and to be able to interpret ISO charts and bearing catalogues.

Machine Technology II

General Learning Outcomes: To develop the apprentice's knowledge of the different applications, maintenance and types of pumps, valves, piping and ancillary equipment To develop the apprentice's knowledge of the regulations, types, applications and maintenance of compressors and ancillary equipment

Welding & Fabrication II

In this intermediate course, students build their foundational knowledge, focusing on welding and fabrication practices. Students will learn how to interpret fabrication and engineered blueprint drawings (including welding symbols). They will continue to practice shielded metal arc welding (SMAW) venturing into 'out of position' techniques. They will explore semi-automatic welding methods, specifically gas metal arc (GMAW) or flux-cored arc welding (FCAW). Students will study the Canadian Standards Association (CSA) W47.1 and W59 codes, which define requirements for structural welding. Throughout their course, students will apply theoretical knowledge to practical scenarios, following both CSA guidelines and Lambton College's health and safety protocols. Emphasis will be on personal protective equipment and safe work practices, both individually and as part of a team.

Electrical & Electronic Controls II

General Learning Outcomes To develop the apprentice's basic knowledge concerning electric and electronic theory.

Drawing & Schematics II

General Learning Outcomes To develop the apprentice's ability to effectively use manufacturers' manuals, and to sketch and draw machine component parts, including sectional views.

Power Transmission

General Learning Outcomes To develop the apprentice's ability to identify, select and install the appropriate transmission system and/or components for a specific application.

Workshop Practice III

This course equips apprentices with a solid understanding of applied mechanics and thermodynamics relevant to the Industrial Mechanic (Millwright) trade. Apprentices will also develop the skills to set up and operate shop equipment and tools to produce parts within prescribed tolerances and standards, and to complete specific work projects. Additionally, they will gain knowledge and basic skills in using precision measuring equipment for machine installation and setup.

Machine Technology III

This course equips apprentices with a comprehensive understanding of various material handling systems and their principles of operation. Apprentices will learn the types, applications, and maintenance procedures of prime movers and ancillary equipment. Additionally, they will learn about the functions of fans and blowers, as well as the procedures, equipment, and benefits associated with preventive and predictive maintenance programs.

Welding & Fabrication III

In this advanced course, students build on their foundational knowledge, focusing on advanced objectives related to welding and fabrication. Continuing with their blueprint interpretation, students will further develop their ability to read fabrication and engineered blueprint drawings. They will explore the basics of gas tungsten arc welding (GTAW), commonly known as TIG (tungsten inert gas) welding. They will study and apply tools and machinery specific to the fabrication industry. They will apply their theoretical knowledge by cutting, forming, fabricating, and welding items with specified parameters. Throughout this course, students will adhere to CSA and Lambton College's health and safety guidelines, emphasizing personal protective equipment and safe work practices both individually and as part of a team.

Electrical & Electronic Controls III

This course aims to develop the apprentice's basic knowledge of electric and electronic terminology, schematics and applications of Programmable Logic Controllers (PLC's).

Fluid Power

This course equips apprentices with a solid understanding of pneumatics and compressed air safety, enabling them to work effectively with pneumatic systems. Apprentices will also learn to identify, select, and install pipe systems and valves for various applications. Additionally, they will learn hydraulic principles and develop the skills needed to perform hydraulic calculations, installations, maintenance, and troubleshooting.

This Employment Ontario program is funded in part by the Government of Canada and the Government of Ontario.

Contact Us

Applied Science, Engineering Technology & Trades